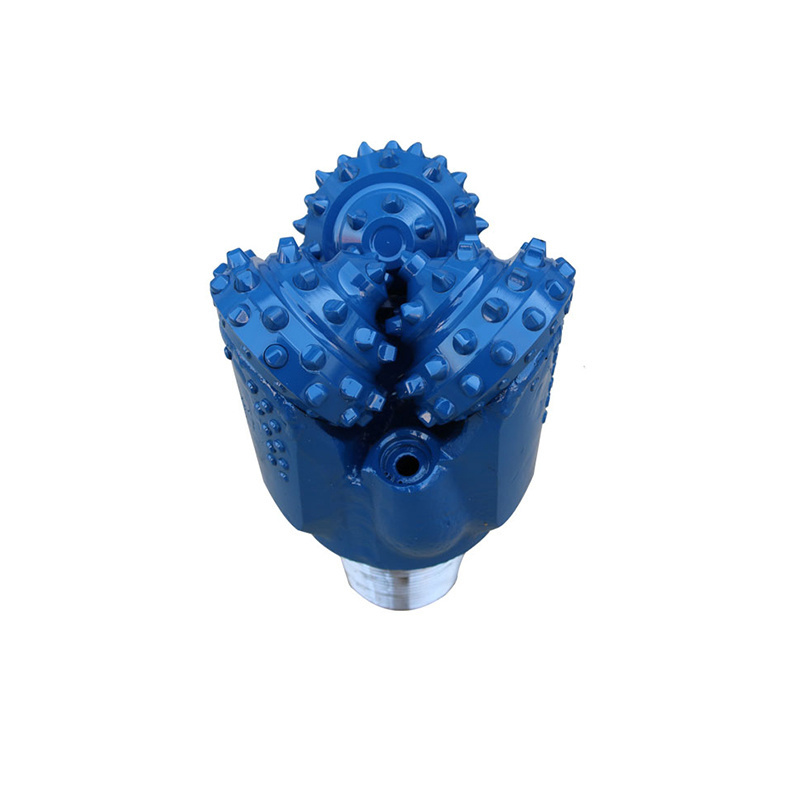

200mm IADC537 Tungsten Carbide Tricone Drill Bit

keyword:

Category:

Details

| Product specifications | |

| Diameter | 7 7/8"(200mm) |

| Bearing type | Rubber Sealed Bearings |

| Tooth Type | (Tungsten Carbide inserts) |

| Circular Type | mud |

| Thread Connection | 4 1/2 API REG |

| Wheel diameter protection (diameter retention) | Available |

| Shirttail Protection | Available |

| Operating parameters | |

| RPM | 120-50 |

| WOB | 80-200 |

| Application Formation |

Soft to medium formations with low compressive strength, such as medium, soft shale, medium soft limestone, medium soft sandstone, medium formation with harder and abrasive interbeds, etc. |

Introduction

TCI Tricone Bit is suitable for soft to hard formation such as clay,mudstone,limestone,sandstone,hard shale,dolomite, etc. Tricone bit with high strength toughness of carbide tooth reduces rate of gear broken and with high-performance wear resistant materials improve the wear resistance and service life of the bit.

Features

1.Bearing Structure: High precision journal bearing with two thrust faces. Ball locked cone. Hardfaced head bearing surface. Cone bearing inlaid with friction reducing alloy and then silver-plated. Abrasion resistance and seizure resistance of the bearing are improved, and suitable for high rotary speed.

2.Cutter: premium carbide teeth having increased resistance to breaking and abrasion, maximum increase cutting structure operating life.

3.Gauge protection: more tungsten carbide inserts are placed in the gauge to reduce the wear in the abrasive formation. It can protect gauge and increases the stability and life of the bit.

4.Nozzle:These nozzles are much sturdier and provide greater flow capacity and maximize fluid distribution to the cones.

Technology

1.Seal and Lubrication: The bearing seal is adapting the high quality HNBR O-ring. The best seal compression and the radial seal structure can enhance the seal performance. The compensation system and the high quality bit grease can limit pressure differential, and greatly increase the lubricating reliability.

2.Six-point Gauge Stability: The design delivers near six-point contact with the borehole wall for unequalled bit stability that protects the cutting structure from damaging lateral blows

3.Motor hardfacing: Tungsten carbide particle hardfacing is applied liberally along the shirttail and extended up the leading edge of the bit leg for additional protection in high-speed, directional or abrasive applications

Application

Soft to hard formations with several hard inter-bed,such as clay/chalk/ compressive mudstone/hard gysum/salt/shale/limestone/dolomite.etc

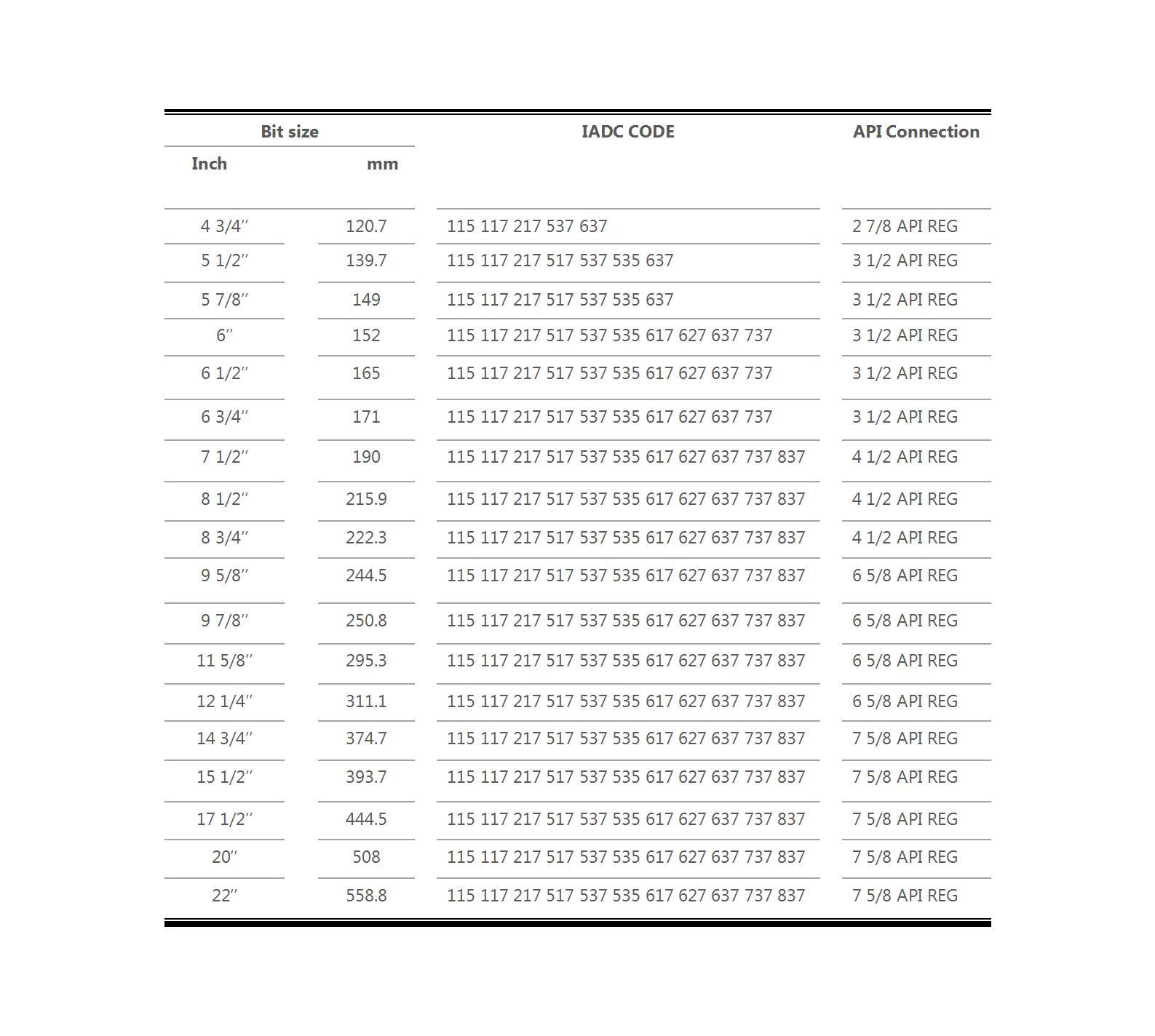

Popular models

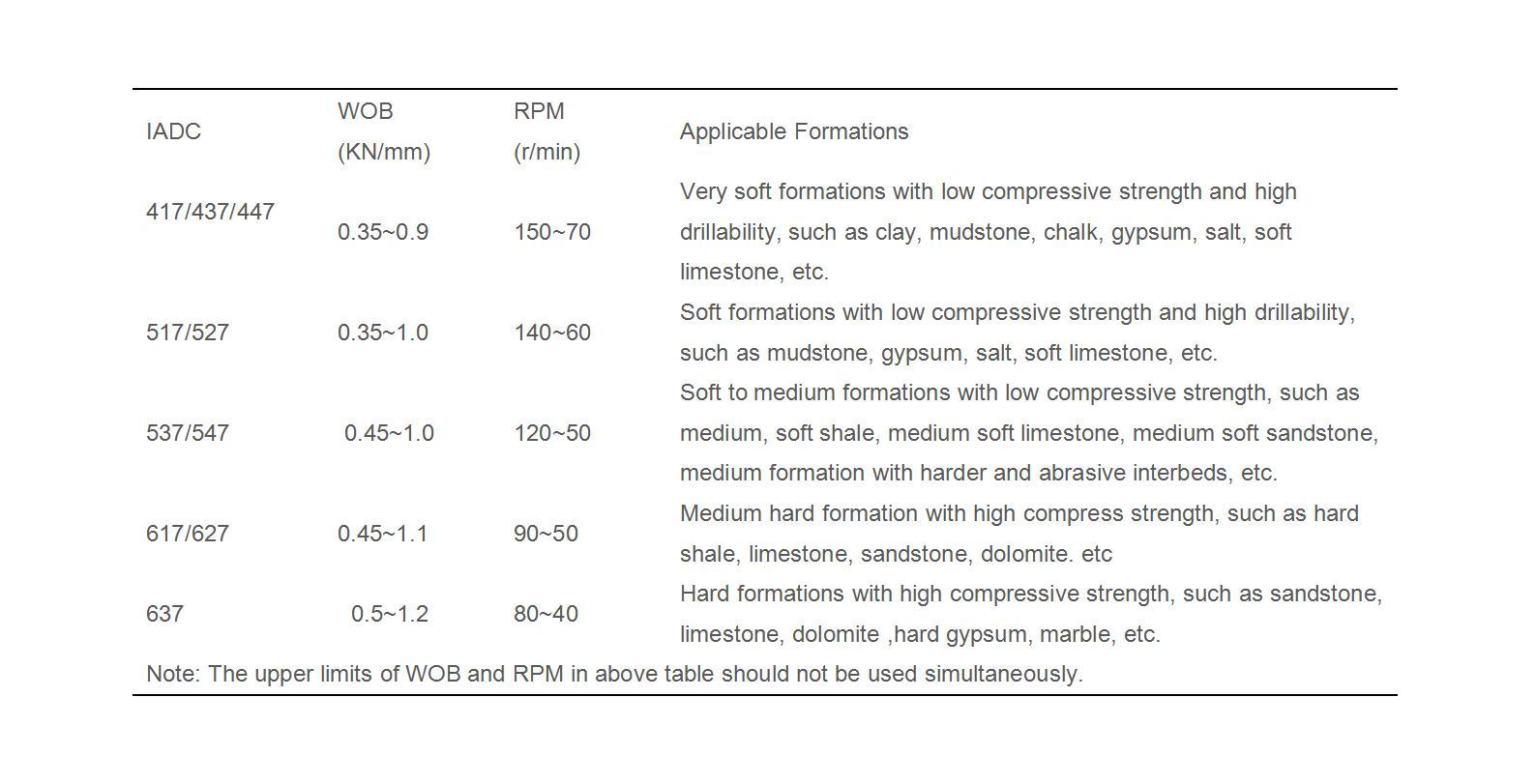

Operating Parameters

Related products

Inquiry

We will contact you within one working day. Please pay attention to your email.